AGV-Automated Guided Vehicles

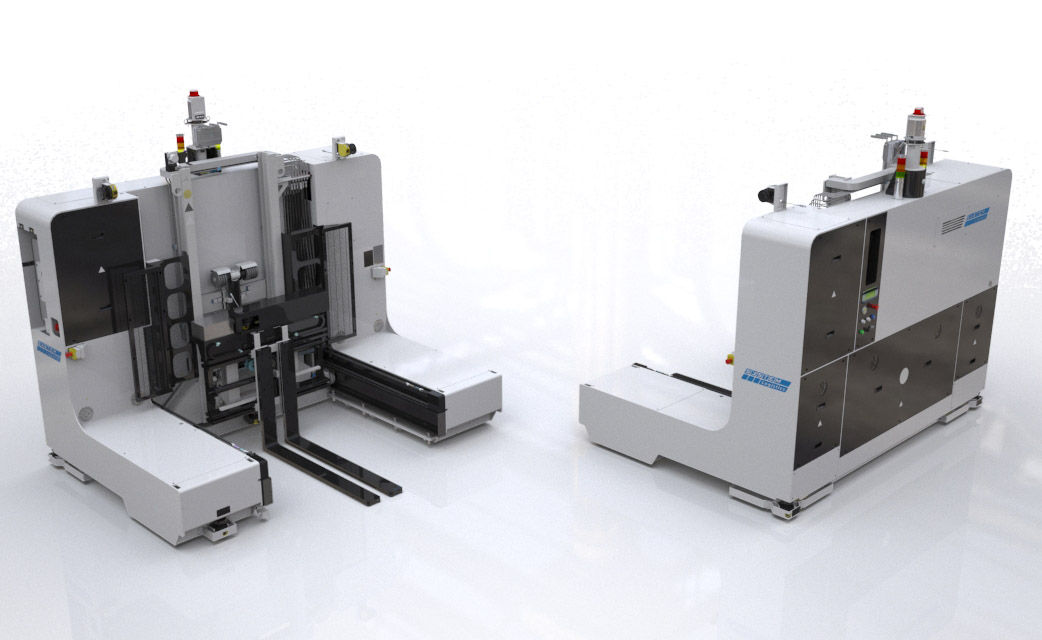

COUNTERBALANCED FORK VEHICLES

These vehicles are the ideal solution for ground handling of pallets, containers and other industrial loading units. They can easily interface with shelves, production lines, and they can also replace manual forklifts.

MAIN APPLICATIONS

This type of vehicle can be used to manage end-of-production lines and line infeed, overlapping loading units, ground storage as well as block storage, in addition to shelf storage.

ADVANTAGES

They can be manoeuvred in narrow spaces and are capable of storing items at high heights. In addition, they can be used to handle different loading units with the same vehicle.

VERSIONS

Our range of counterbalanced vehicles differs in terms of loading capacity and reachable height. They can all be customised with different optionals, from additional safety sensors to different handling devices, in order to meet the customer's specific needs.

shark

Shark is the most compact and versatile product in our range. It is capable of moving in all directions and working in narrow spaces. Its dimensions are actually similar to those of the load carried.

MAIN APPLICATIONS

Shark is mainly used to connect the production lines with the automatic warehouse. It can also be used to handle products between the various internal conveyor systems, to serve the robotised stations as well as the automatic picking bays.

ADVANTAGES

The ability to handle loads without using fixed mechanical structures makes Shark extremely flexible and modular.

VERSIONS

This vehicle may come equipped with roller tables, chains or lifting devices of various type, depending on the intended application.

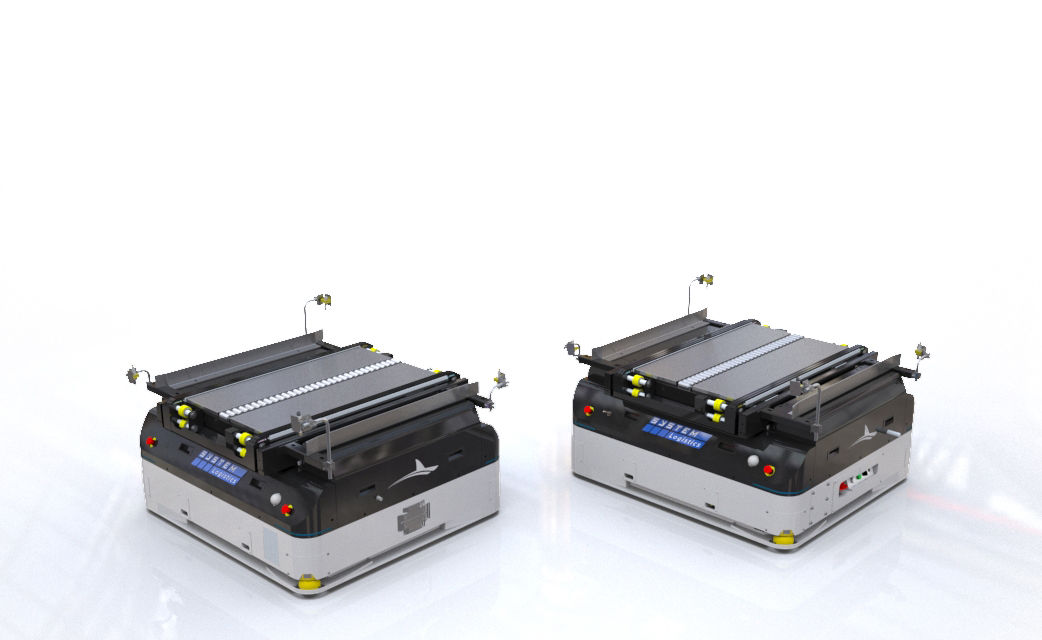

CONVEYOR DECK VEHICLES

These vehicles can be used to handle products between different conveyor systems and to transport several loading units at the same time in narrow spaces.

MAIN APPLICATIONS

They are ideal to connect the operations between end-of-line handling and other system automations, and between the latter and the material infeed stations towards the production lines.

ADVANTAGES

These vehicles are capable of carrying several loading units at the same time and feature a high operational capacity, so that they can be used with different automatic conveyors with just a few modifications. Since there are no fixed structures, the surrounding area remains open and so allows passage of other vehicles or people.

They provide high load stability and can carry from one to 4 loading units at the same time, thus optimising material handling time.

VERSIONS

The range includes vehicles that differ in terms of number of loading units carried and kinematics. They can be equipped with chains or roller tables, according to the specific needs.

FORK QUAD VEHICLES

These vehicles are suitable for handling several loading units among operational positions at different heights, thanks to the forks they are equipped with.

MAIN APPLICATIONS

These vehicles are the ideal solution to handle the loading units from the finished product outfeed to the storage areas, be they on the ground, at different heights or within other industrial automations. In addition, they can be used to handle loading units among the different automations in the system, as well as the material infeed stations towards the production lines at different operational heights.

ADVANTAGES

As opposed to the Quads, the loading units are picked and stored by means of forks, and can therefore operate at different heights. They can carry several loading units at the same time, without needing to modify the existing mechanical structures.

VERSIONS

Our range of forked quad vehicles varies in terms of number of loading units handled.

OUTRIGGER VEHICLES

This type of automatic vehicle is the ideal solution to handle loading units of various dimensions, weight and type. The idle wheels are positioned next to the pallet barycentre, thus assuring high capacities and manoeuvrability in narrow spaces.

MANY APPLICATIONS

These vehicles are particularly suited for operations within production lines and conveyor systems of different kinds, to connect different types of automation systems and storage of heavy loading units.

ADVANTAGES

Because of their high stability, they require shorter manoeuvring spaces and are also suited to low capacity floors.

VERSIONS

System Logistics manufactures different AGV Outrigger versions that differ in capacity and height. Also these vehicles can come equipped with different accessories, based on the design specifications.

CUSTOMISED VEHICLES

System Logistics can meet the different needs of a multi-faceted and continually evolving market, and can respond to the specific customer requirements by designing ever newer vehicles with innovative features for non-standard applications.

MAIN APPLICATIONS

Tailor-made vehicles can be designed both in the event of shelves with narrow aisles, as well as for handling and storing non-standard loading units (high weights and dimensions), in environmental conditions where strict hygienic rules apply.

ADVANTAGES

The vehicles can be customised based on the design specifications, to meet the customer's needs.