LogiMate Solutions

THINKING PICKING OUT OF THE BOX

For almost half a century at System Logistics we have been planning the future of logistics and intralogistics. We are a company made of people, today we have over 400 resources in the Italian headquarters and 8 offices around the world. We offer the market the innovation and perfection that only made in Italy technology can guarantee and this is recognized globally.

We strongly believe that research and development are at the center of our work and allow us to respond to the needs of customers who are increasingly attentive to technology and in need of real performance improvements.

Our thinking out of the box motivates us every day to give more and more and to seek what can make a difference, sometimes even just a detail.

LogiMate is the tangible expression of our way of approaching work, the result of research and development of a new system capable of offering the market what was really missing by bringing logistics "out of the box".

We move it as it is

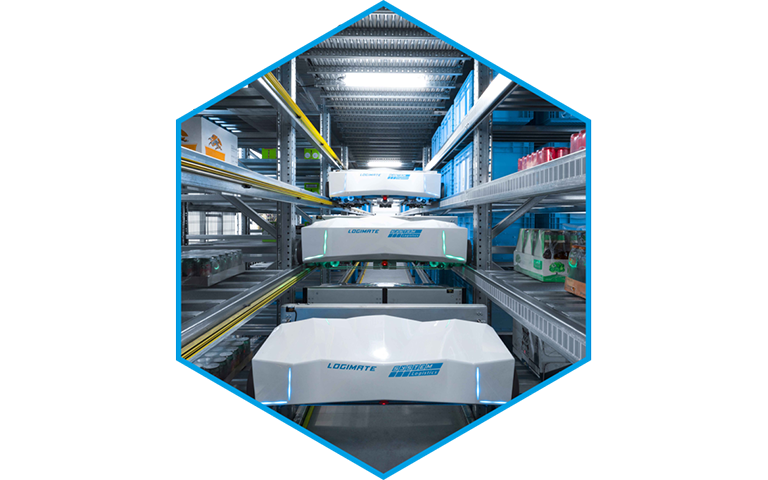

LogiMate uses a breakthrough solution based on the patented 3-Elements hooking units for improved contact area and handling stability of unstable and deformable goods with no supporting media.

Enhanced load capability

Sequential twin load capability for vehicle job optimization up to 610 x 410 mm. Enhanced maximum payload for heavy merchandise: 2x50 Kg or 1x100 Kg. Wide dimensional range for higher flexibility from 150*100 mm to 880*650 mm.

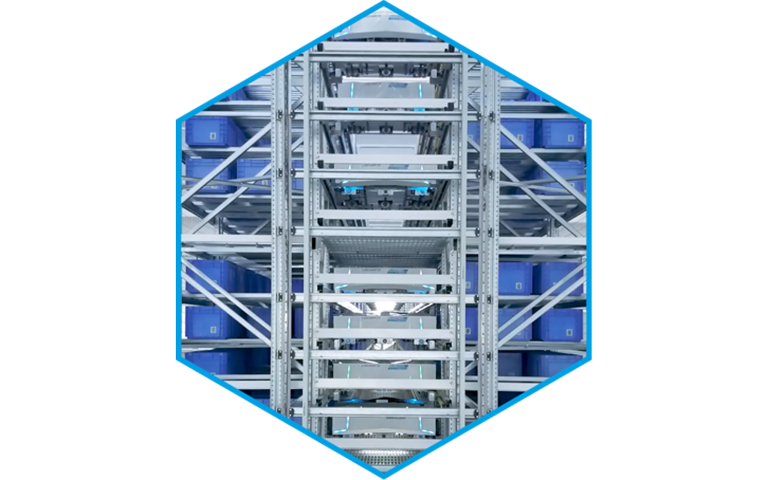

Higher storage density

LogiMate offers flexible multi-deep storage with goods compacting up to 8-deep, based on dimensions. Modular design allows for any rack height option up to over 20 meters, based on requirements.

Embedded sequencing

Thanks to the unique three-dimensional configuration, the system offers the possibility of integrating the elevators inside the shelf profile and distributing them longitudinally, releasing the number of elevators from the blocks of shuttles.

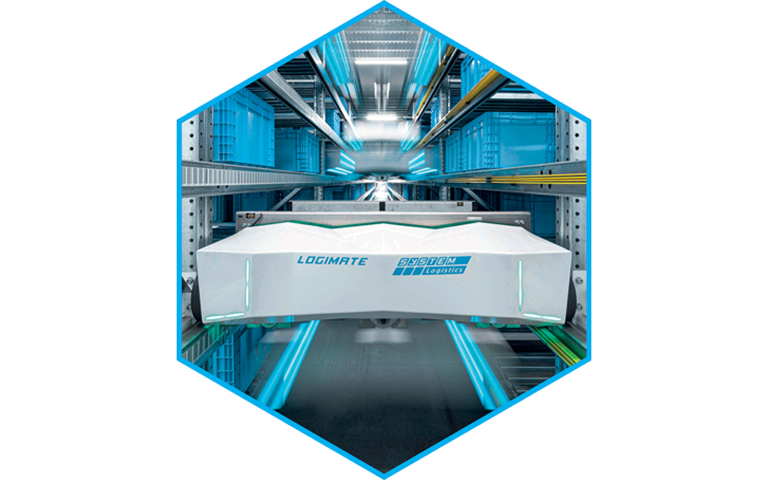

FLEXIble AND MODULAR

LogiMate allows great flexibility in the layout design of complex systems, ensuring the overcoming of the performance limits and the sequencing capacity of the other systems on the market. The flexibility that results from the modularity responds to every needs.

Energy efficiency

The energy efficiency is the result of the combination of three main elements: the use of Super Capacitors on elevators, the braking energy recovery, both on the vehicle and on the ground, and the automatic adaptation of dynamics according to the load.

Modular Order Picking System

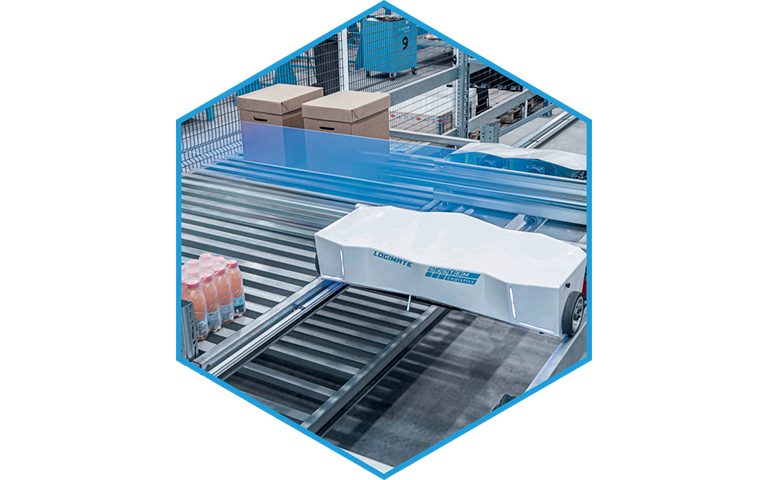

MOPS solutions are specifically designed for working natively with an extensive range of FMCG package types, making it the perfect solutions for mid / high-volumes order fulfillment centers within the Food, Beverage & Grocery industries.

MOPS is the picking system for the fully automated creation of mixed pallets. The items are directed to an automatic palletizer based on the optimum composition of the client’s (mixed) pallet determined by the Best Fit software. Best Fit algorhythm is an algorhythm that manages the pallet building for every customer order, elaborating the best physical composition and the correct palletization sequence, evaluating many different variables at the same time.

MOPS can deal with a large range of different products (over 95% of products managed within large-scale distribution). Packages are handled without support trays, so the number of items that can be managed through MOPS is very variable: from a couple hundred to a few thousand items.

Each Picking

Goods-to-person (GTP) solutions combine custom-designed, ergonomic stations with operator-friendly control systems to greatly improve order fulfillment efficiencies.

Products are stored within the system and automatically transported directly to the operator as needed for picking, offering accurate inventory and pick data.

Workstation screens display exactly which item the operator needs to pick, this eliminates order errors that are often a challenge in high-speed and high-demand environments.

Goods to person technologies are easily scalable to match growing demand and increase in SKUs.